Metal Roofing Fabrication – Things You Didn’t Know

No matter what you’re building, metal roofs, compared to conventional roofs, will last longer against the elements. That extra durability means savings in the long run. One of the most common questions asked is, “What makes metal roofing different than traditional roofing?” The unique interlocking system between panels acts a shield against the elements. Less roofing maintenance and roof replacements long-term. At Metal Roofing Supply, we have all the equipment necessary to deliver the best selection of roofing products.

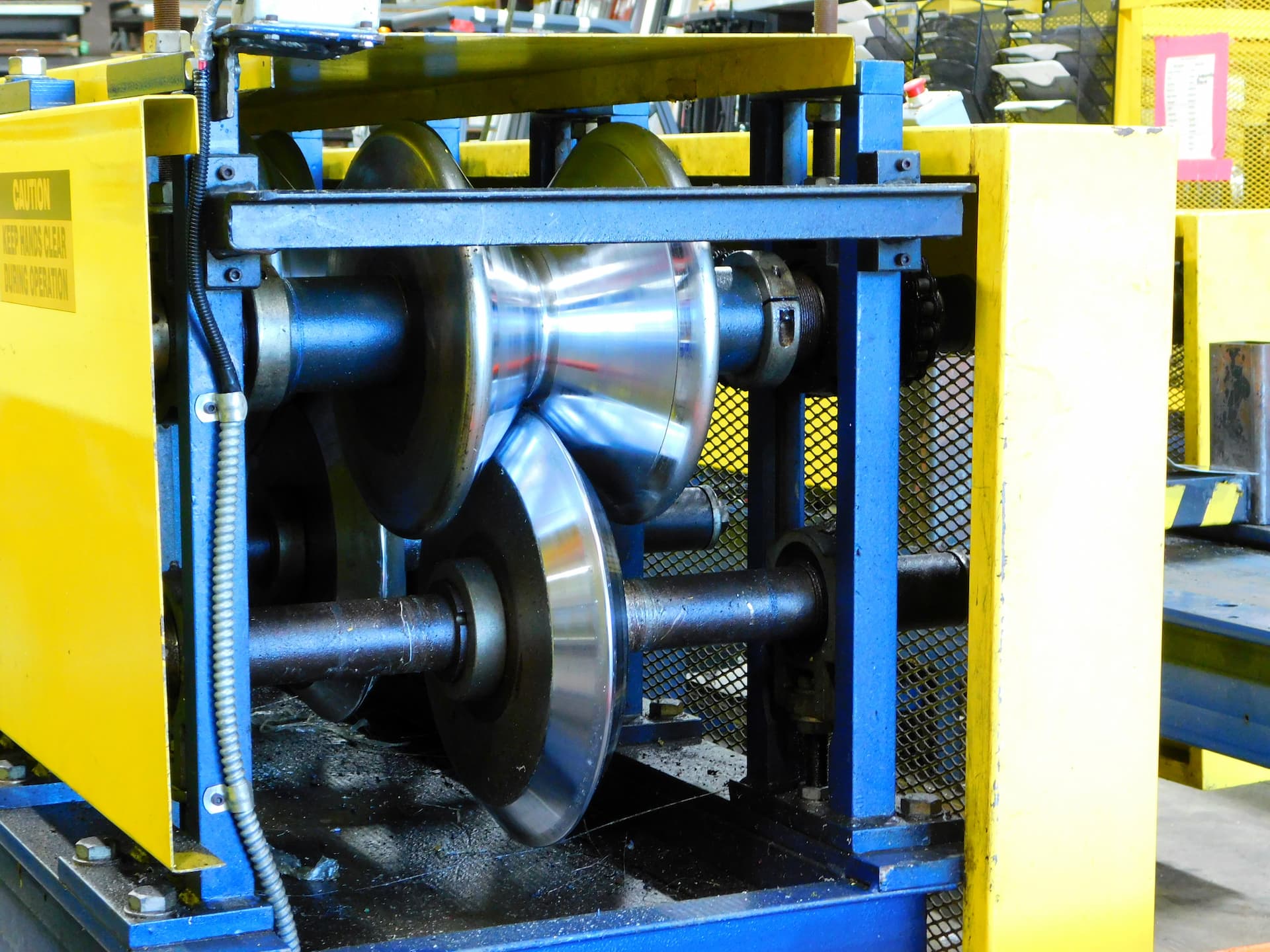

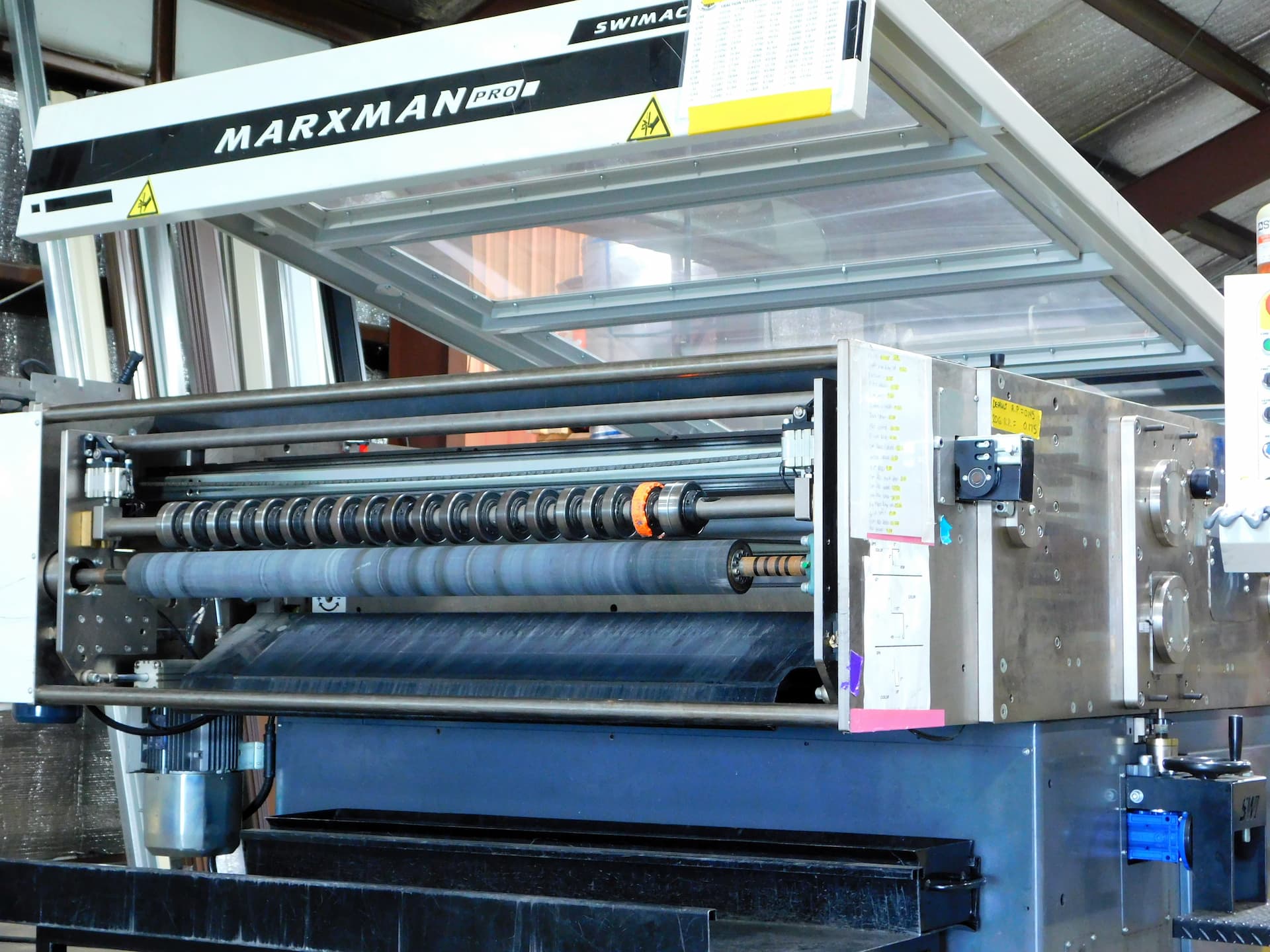

Equipment

Some of the manufacturing machines we have at our main plant include:

- Roll Forming Machine

- Decoiler

- Back Sheer

Fabrication

Your metal roof begins as a thin, flat rolled coil. These metals are refined and placed into a rolling machine to reduce the thickness and achieve desired gauge.

- Receive the pre-painted coils

- Metal coils are placed into the roll-former

- A computer is programmed to cut the metal sheets to any length

- The coil moves through the roll-former, bending and cutting it to shape

- After the order is run, it is banded and loaded out for delivery

Accessories

In addition to the panels, you must consider the extra items that are required to complete your metal roof. Additional materials you would need to complete the roof installation that you can find at Metal Roofing Supply may include:

- Residential Rake

- Ridge Caps

- Valley

- Roof Flashings (Boots)

- Sealant

- Fasteners (Screws)

- Trim

- Foam Closures

- Hat Channel